Before you start

The parquet should normally be laid free floating. It should be laid on a clean, dry, level and firm surface without any cracks. Concrete flooring, chipboard, old floorboards, plastic flooring and felt type wall to wall carpets are suitable surfaces. However, the parquet should not be used as a self-supporting floor covering laid on joists.

Before laying, ensure that the surface is dry. The parquet can be laid without damp proofing if the relative humidity (RH) is below 60%. If the RH is 60-90% a damp proofing has to be provided. Lightweight concrete proofing has to be provided. Lightweight concrete flooring in rooms without basements and warm or damp rooms should be covered with damp proofing material consisting of 0.2 mm plastic sheeting before the parquet is laid.

Check the surface of the sub-floor for unevenness using a rule or a piece of the parquet. The maximum tolerance for the unevenness of the surface should be 2 mm over 700 mm or 4 mm over 2000 mm. Concrete flooring should be levelled down with suitable fillers and sub-floors made of particleboard or wood should also be sanded down. Before sanding, check the fastening of the old wooden flooring and nail down if necessary. A damp proofing material consisting of 0.2 mm thick plastic sheeting is always recommended for concrete sub-floors. The film is laid with the edges overlapping by about 20 cm and the seams sealed with adhesive tape. Place a 2 mm underlay made of rubber, EVA underlayment or similar material between the subfloor and the parquet to cover any unevenness and to absorb the noise.

Tongue & Groove

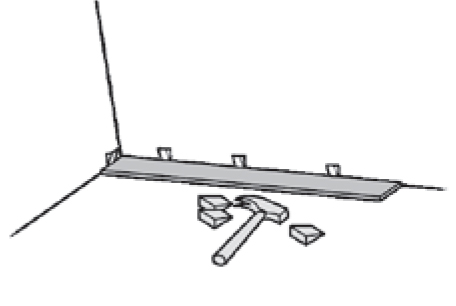

Step 1

An expansion gap of at least 10 mm must be provided between the edges of the parquet boards and the wall or other fixed structures, such a heating pipes or door frames. In very large rooms this gap is not sufficient and in such cases the necessary gap width is calculated by multiplying the maximum room width (in metres) by 1.5 mm. Use wooden wedges for maintaining the expansion gaps during installation.

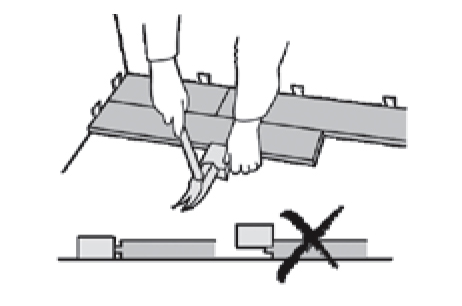

Step 2

We recommend that the parquet boards are laid parallel to the direction of the main light source. If the parquet is to be laid on top of old wooden flooring, the boards should be laid perpendicular to the direction of the old flooring. We recommend that the first board be laid against the wall with the grooved edge facing the wall. If the wall you start laying against is not straight, you will need to fit the boards to the shape of the wall by laying the first row against a string. Begin each new row with an offcut left over from the previous row. The distance between the end-joints of adjoining boards must be at least 50 cm.

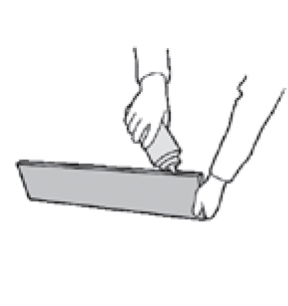

Step 3

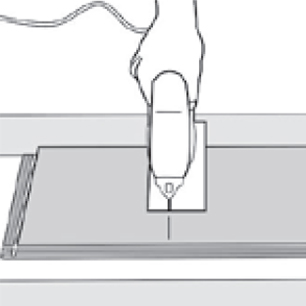

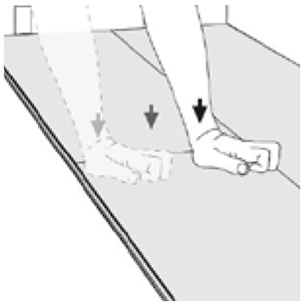

Apply the glue using a bottle with a long nozzle and spread into the grooves of the boards. PVAC glue is used.

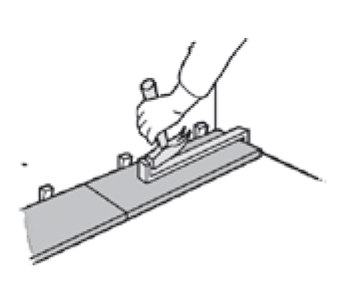

Step 4

Tap the individual boards into the groove using a protective wood block of 30 - 40 cm in length between the hammer and the tongue edge. Do not use force.

Step 5

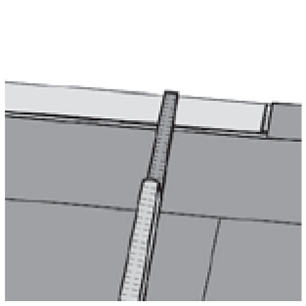

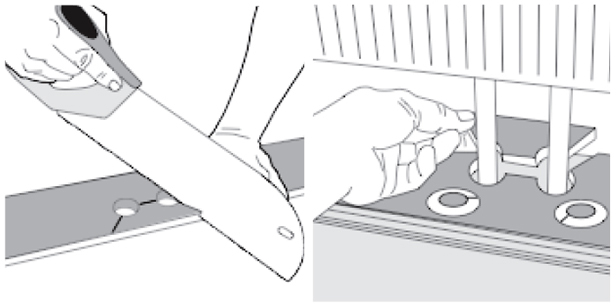

For pipe lead-throughs, drill holes with a diameter about 20 mm larger than of the pipe. Saw out a piece as shown in the diagram. Insert the sawn out piece after the parquet floor has been laid.

Step 6

Saw the last row of parquet into its correct width taking into account the expansion gap required. Use wooden wedges for the fixing of this edge.

Step 7

Chisel may be used for cut-offs.

Step 8

Remember to adjust the clearance between the door frame and the floor by about 14 mm so that the parquet can be laid underneath. After the glue has dried, cover the expansion gap with skirting and fasten by nailing or with dowels. The skirting should not rest too tightly on the parquet otherwise it will prevent free movement of the flooring. Cover pipe lead throughs with fittings.

Step 9

Cover the joints between the parquet and other floor materials, e.g. in adjoining rooms with thresholds and trims. Remember to leave an expansion gap under the trims.

Additional Notes:

The parquet is supplied as factory finished. It is advisable to open the packages containing the parquet planks one by one during the laying process.

Check the boards against possible defects before laying. A defective board can be either laid as the last one, or used as a part plank of a beginning row or end row or it can be exchanged for a new one at the retail outlet. The amount of leftover cutting waste should be about 3 %. We recommend that furniture legs are provided with felt pads in order to prevent scratches on the parquet.

Maintenance :

The daily cleaning is carried out by using a broom or vacuum cleaner. Parquet can also be cleaned with a well wrung damp mop. Parquet cleaning liquid should be added into the water. Before putting the parquet into use for the first time we recommend to treat the surface with plain parquet conditioner. Do not use soft soap, neutral soap, detergents, stain removers or products based on acetone on the parquet floor.

Välinge 5Gc Click

Installation

Step 1

Start in the left-hand corner of the room. Place a distance about 10 mm thick to the left. And position the plank to the wall (tongue face into the toom).

Step 2

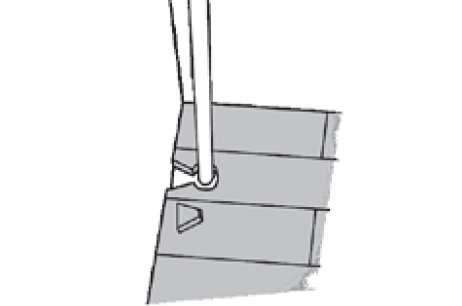

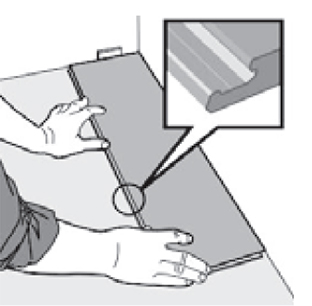

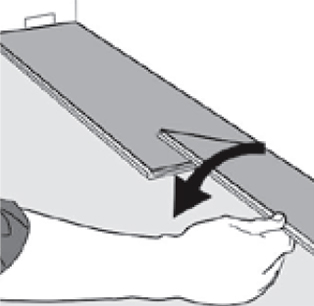

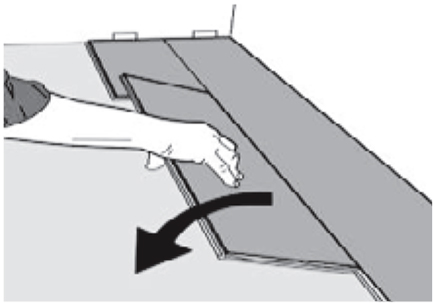

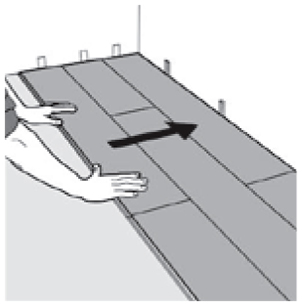

Place second plank gently and tight to the short end of first plank. Fold down the panel down in a single action movement. During the fold down make sure the panels are tight against each other. Afterwards press or slightly knock at the short end just installed.

Step 3

At the end of first row, put a distance about 10mm to the wall and measure the length of the last plank to fit.

Step 4

Cut with a jig saw hardwood face turned down or with a handsaw with hardwood face up.

Step 5

Second row. First plank minimum 500 mm. Put a distance to the wall about 10 mm thick.

Step 6

General: Minimum distance between short end of planks in parallel rows shall not be less than 400 mm.

Step 7

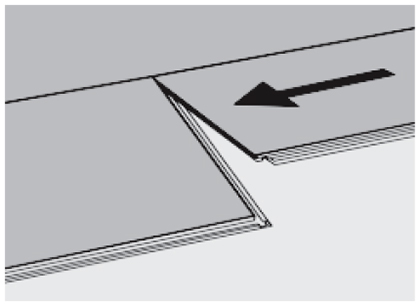

Second plank, second row: Place the panel gently and movement tight to the short end of the previous.

Step 8

Fold down in a single action with a slight press to the short end of the previous. During fold down make sure the panels are tight against each other.

Step 9

Press or knock slightly along the short end of the installed panel.

Step 10

After 3 rows, adjust the distance to front wall by placing distances about 10 mm to the wall.

Step 11

Last row (and perhaps also first row): Minimum width 50 mm. Remember the approximate 10 mm distance to wall! Cut the panels lengthwise and glue the short ends.

Step 12 & 13

For installation of radiators, please drill the holes 20mm larger than the diameter of pipes.

Disassembling

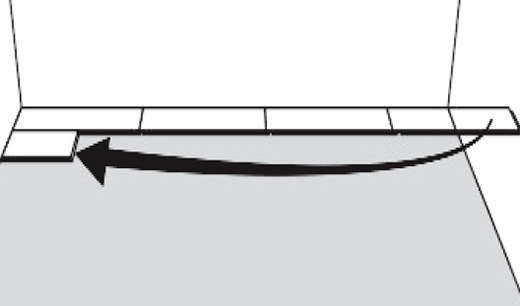

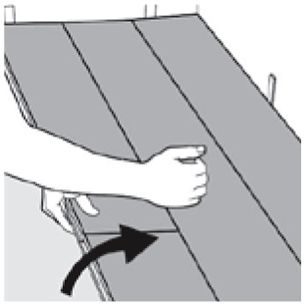

Step 1

Separate the whole row by carefully lifting up and slightly knocking just above the joint. Fold up and release the whole long side.

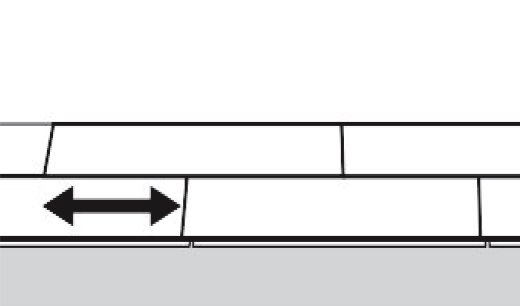

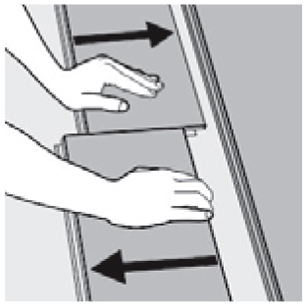

Step 2

Disassemble the panels by sliding horizontally. (Do not fold up!).